Events

Ortis: Automation in Orthotics & Prosthetics (AAOP)

Live Trade Show:

Join us at the AAOP 49th Annual Meeting in Nashville, TN March 1st – 4th, 2023 at Roboticom’s (Booth #1026) to learn more about Ortis™.

Learning points:

– Why robotic automation instead of manual milling?

– Will automatic robotic milling improve outcomes?

– Can robotic milling reduce worker injuries?

– Are there any constraints for high variety, low volume manufacturing?

– Is it easy to program Ortis™ in-house?

Client Testimonials:

HiTek | Tillges Technologies

SandRob: SpaceCom Trade Show

Join us at the Spacecom Orlando, Florida March 21st – 23rd (Booth 513) to learn more about SandRob.

SandRob is the only robotic solution addressing the needs of all surface finishing processes: sanding, polishing, trimming of complex shapes at any material and size. A force feedback system allows to precisely control the force exerted on the treated surface, to achieve different results on the same workpiece, all while the speed control is continuously controlled via software.

Ortis: AOPA National Assembly

Join us at the AOPA National Assembly in San Antonio, TX September 28 through October 1st, 2022 at Roboticom’s (Booth #342) to learn more about Ortis™.

Learning points:

- What is ORTIS™️ and why is it regarded as the original O&P carving robot?

- What level of automation am I able to reach with ORTIS™️?

- What are the five myths of automation?

Client Testimonials:

Tillges Technologies | Biotech Limb & Brace | East Coast Orthotics and Prosthetics O&P

SandRob: IWF – The International Woodworking Fair

Join us at the International Woodworking Fair at Georgia World Congress Center 285 Andrew Young International Blvd. Atlanta, GA 30313 (Booth BC429) to learn more about SandRob.

SandRob is the only robotic solution addressing the needs of all surface finishing processes: sanding, polishing, trimming of complex shapes at any material and size. A force feedback system allows to precisely control the force exerted on the treated surface, to achieve different results on the same workpiece, all while the speed control is continuously controlled via software.

AUGUST 23 – 26, 2022 EXHIBIT HOURS

Tuesday – Thursday 8:30 AM – 5:00 PM

Friday 8:30 AM – 2:00 PM

SandRob: Aerospace & Defense Supplier Summit

Meet Roboticom at the live Aerospace and Defense Supplier Summit, a platform that brings together key players of aerospace industry on April 11-13, 2022 in Seattle, WA, USA.

Learning points:

- At A&DSS our team will illustrate how robotic automation is changing the aerospace industry to improve productivity and affordability.

- All this thanks to new technologies like SandRob, our surface finishing robot.

Our robotic solution can automatically perform operations like sanding, polishing, bonding, trimming, and cutting on complex shapes of any size. SandRob has already found many applications in industries where composite materials are widely used, such as aerospace, automotive, transportation, design, and sports equipment.

SandRob & ScultoRob: COVERINGS – The Global Tile & Stone Experience

Join us at the Las Vegas Convention Center (Booth N648) to learn more about SandRob and ScultoRob

SandRob is the only robotic solution addressing the needs of all surface finishing processes: sanding, polishing, trimming of complex shapes at any material and size.

A force feedback system allows to precisely control the force exerted on the treated surface, to achieve different results on the same workpiece, all while the speed control is continuously controlled via software.

ScultoRob is a 7 axis robotic system for milling and turning operations on models and prototypes made of Stone, wood and other materials. ScultoRob can be used as a flexible milling center, combined with the versatility and easiness of ARPP®, the software expressly developed to bring out all its potential.

APRIL 5 – 8, 2022 EXHIBIT HOURS

Tuesday April 05, 2022 10:00 a.m. – 5:30 p.m.

Wednesday April 06, 2022 10:00 a.m. – 5:30 p.m.

Thursday April 07, 2022 10:00 a.m. – 5:30 p.m.

Friday April 08, 2022 10:00 a.m. – 3:00 p.m.

SandRob: World Composite Week

Meet Roboticom at the virtual World Composite Week, a platform that brings together key players of composites industry on May 26th-27th 2021.

Learning points:

- At WCW our team will illustrate how robotic automation is changing the composites industry to improve productivity and affordability.

- All this thanks to new technologies like SandRob, our surface finishing robot.

Our robotic solution can automatically perform operations like sanding, polishing, bonding, trimming, and cutting on complex shapes of any size. SandRob has already found many applications in industries where composite materials are widely used, such as aerospace, automotive, transportation, design, and sports equipment.

Ortis: Automation in Orthotics & Prosthetics (AAOP)

Join this live webinar to learn about the applications of the Ortis™ robotic system in milling of foam material allowing to create any model (positive or negative) for the production of orthoses and custom prosthesis. Roboticom USA is excited to be joining our #orthotics and #prosthetics colleagues and friends May 4th–7th at the first fully virtual Academy Annual Meeting. We can’t wait for #ExperienceAAOP2021!

Learning points:

– Why robotic automation instead of manual milling?

– Will automatic robotic milling improve outcomes?

– Can robotic milling reduce worker injuries?

– Are there any constraints for high variety, low volume manufacturing?

– Is it easy to program Ortis™ in-house?

Client Testimonials:

HiTek | Tillges Technologies

TO JOIN OUR WORKSHOP REGISTER FOR AAOP VIRTUAL AT:

https://www.mylibralounge.com/sites/2021aaopaamss/Attendee/en/welcome/

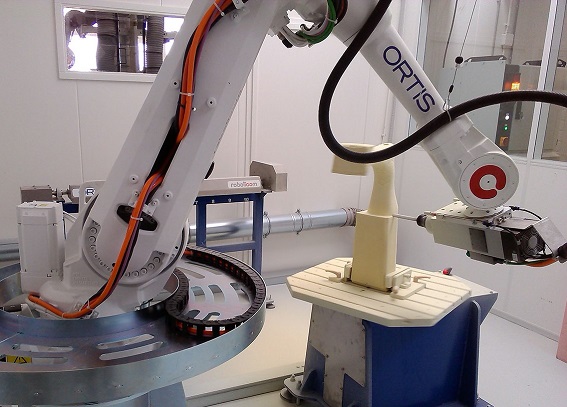

ScultoRob: The Robot That Shapes Your Ideas

Watch this recorded webinar to learn about ScultoRob™, its fields of applications, and how robotic automation can streamline the most delicate manufacturing processes in various industries: sculpting & artistic work, engineering design & prototyping, architecture, interior & exterior design, furniture, and more. In this recorded session, we demonstrate ScultoRob™ and how it can automate carving, polishing, cutting, and trimming process of marble & stone, metal, and other materials.

Learning points:

- What is ScultoRob™?

- Different materials and object shapes that can be carved with ScultoRob™.

- How ScultoRob™ can improve operational efficiency and production quality.

- Software demo: offline programming for low-volume, high-variety production.

Client Testimonials:

Precision Stone, Inc. | Mark Mennin, Inc.

SandRob: Robotic Surface Finishing For Composites

Watch this recorded webinar to learn about the applications of the SandRob™ robotic system in surface finishing operations of composite material on complex shapes, and its applications in sanding, grinding, polishing, and trimming for composite surface finishing for automotive and aerospace industries.

Learning points:

– Why robotic automation instead of manual surface finishing?

– Will automatic robotic surface finishing improve outcomes?

– Can robotic surface finishing reduce worker injuries?

– Are there any constraints for high variety, low volume manufacturing?

– Is it easy to program SandRob™ in-house?

Client Testimonials:

Globe Composites | Delastek

Ortis: Automate & Grow Your O&P Business

Watch this recorded webinar to learn about ORTIS™️ (The original O&P carving robot) and how automating production with this robotic system can help O&P and Central Fabrications facilities of all sizes automate the most delicate manufacturing processes.

Learning points:

- What is ORTIS™️ and why is it regarded as the original O&P carving robot?

- Why should I replace my old 3-axis carver with a 7-axis ORTIS™️?

- I already have a CAD software, do I need to change it?

- Do I need an engineer to program ORTIS™️?

- What level of automation am I able to reach with ORTIS™️?

Client Testimonials:

Tillges Technologies | Biotech Limb & Brace

SandRob: Robotic Surface Finishing For Composites (ACMA)

Watch this recorded webinar to learn about the applications of the SandRob robotic system in surface finishing operations of composite material on complex shapes, and ways it can address the most common manufacturing challenges.

Learning points:

– How do I reduce health hazards and worker injuries through robotic automation?

– How can I maintain consistent output quality and improve production outcomes?

– What are the applications of robotic platforms in high variety, low volume manufacturing?

Hosted By:

American Composites Manufacturing Association (ACMA)

Robotic Solutions

ORTIS

SandRob

ScultoRob

Contact Us

19810 Asheville Highway Suite 101, Landrum, South Carolina 29356

hello@roboticom.us

(949) 238.6323