SandRob

Advanced Robotic Solution for ALL your surface finishing needs.

About SandRob

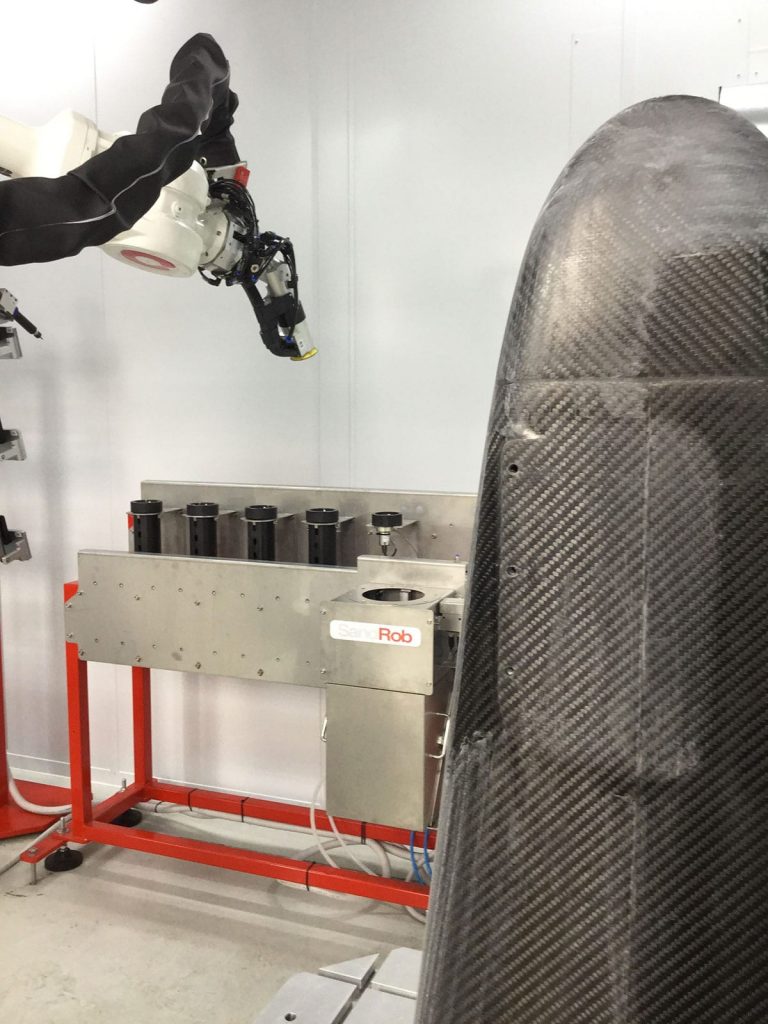

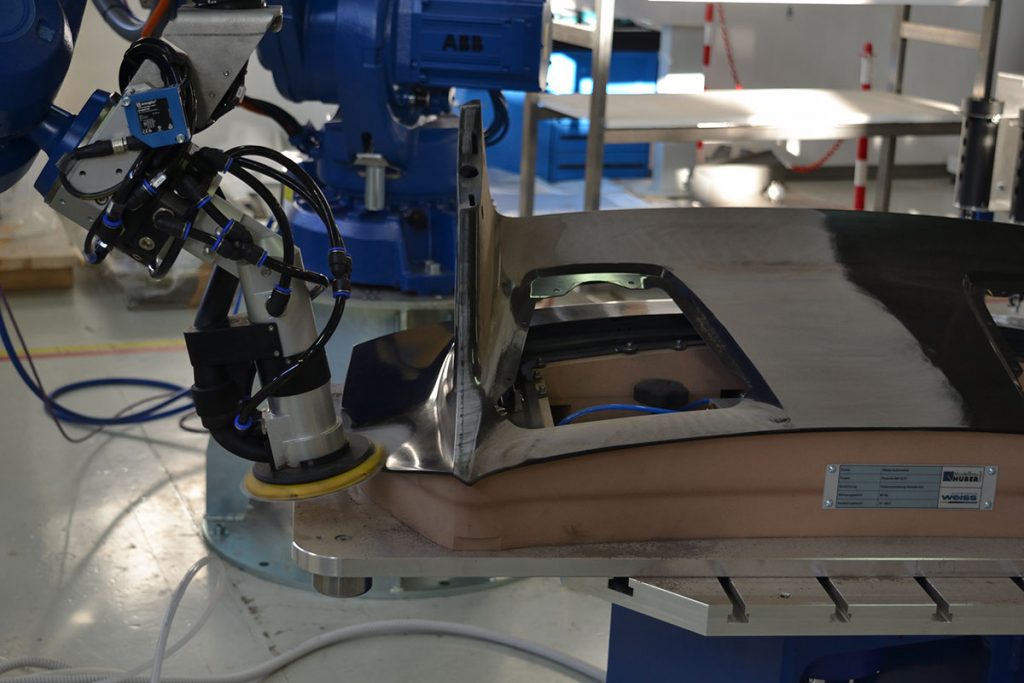

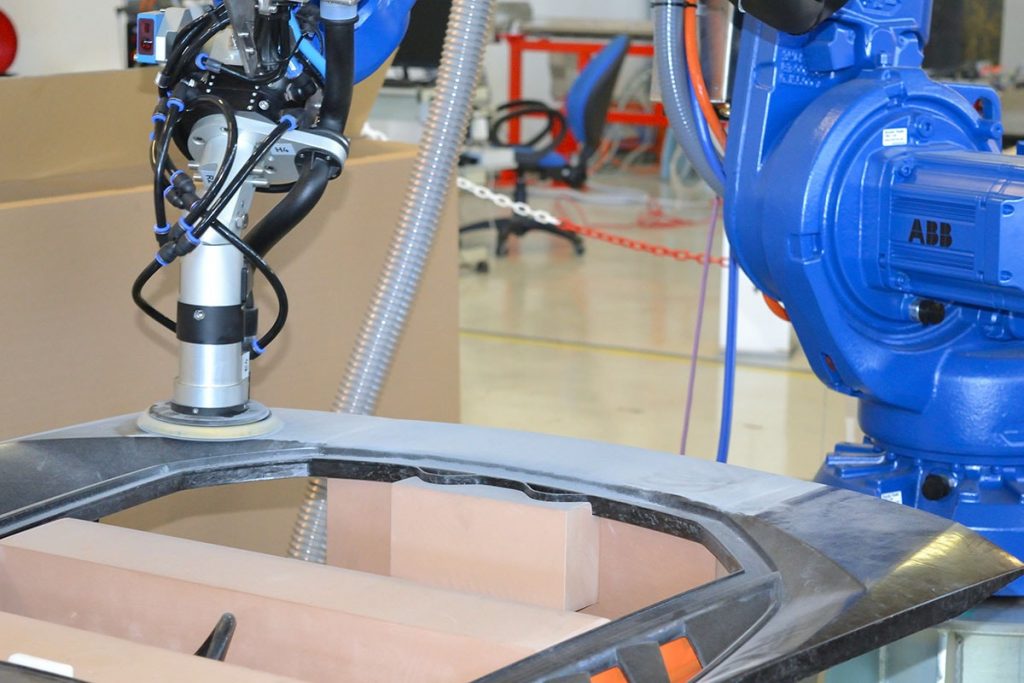

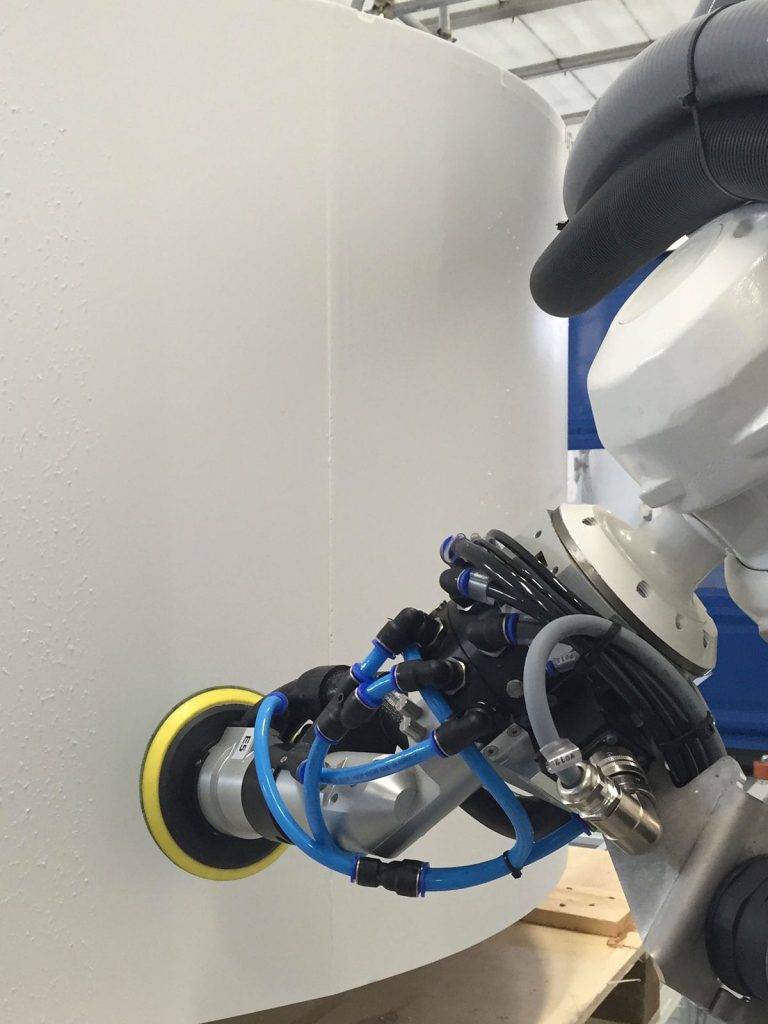

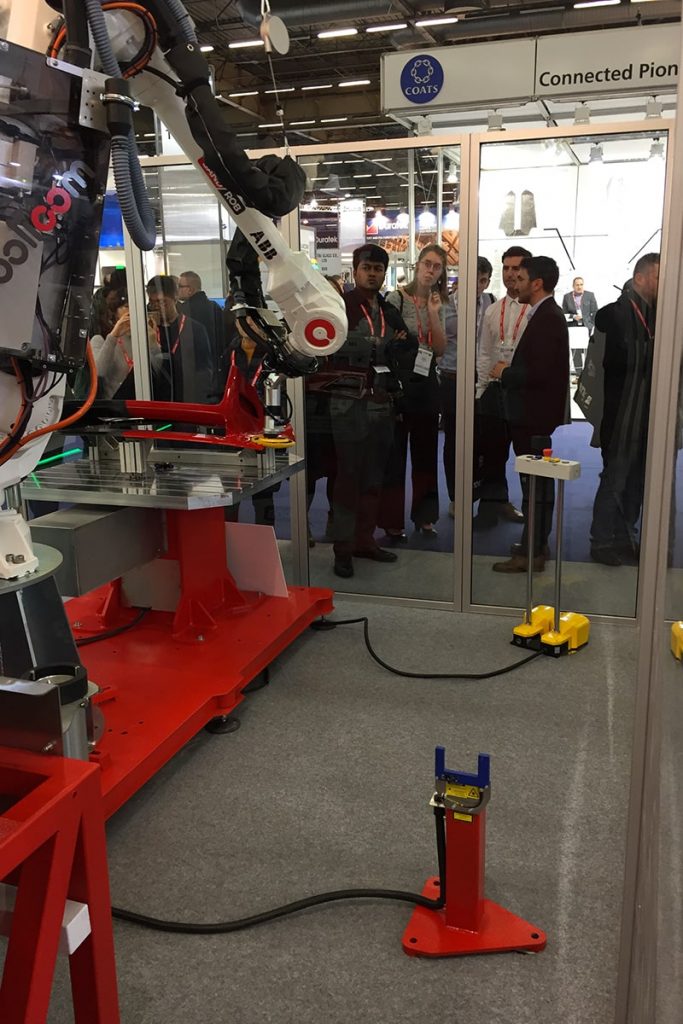

SandRob is the only robotic solution addressing the needs of all surface finishing processes: sanding, polishing and trimming of complex shapes of any scale or size. An active force feedback system allows to precisely control the force exerted on the treated surface, to achieve different results on the same work-piece, all while the speed control is continuously controlled via software.

SandRob delivers quality, consistent results. Automating your production process with SandRob allows you to produce more while reducing your production time and associated risks.

- Consistent Quality Output Every time

- Safe & Risk-free Working Conditions

- Significant Increase in Output Quantity

- Significant Reduction in Waste (Time & Material)

Features

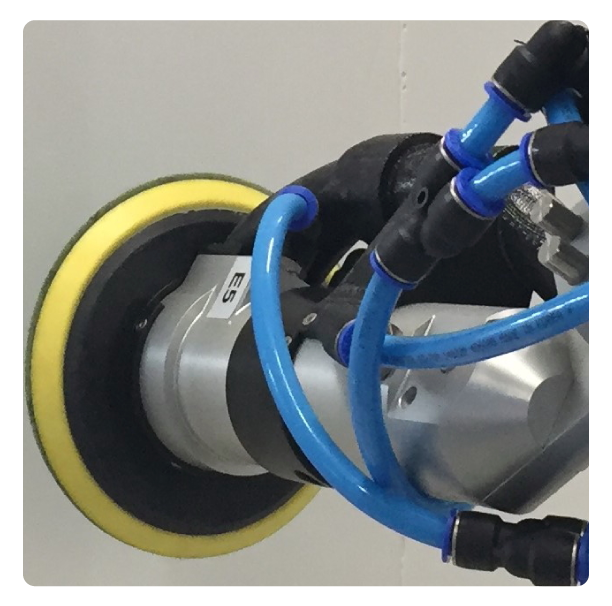

- Selectable end-effector according to the process

- Electronic speed regulation, set by the software

- Proprietary automatic end-effector and sandpaper change system

- Compensation system to manage the abrasive pressure force

- Sensor (touch probe or laser) to detect and adjust the sanding process

- Dust extraction system

- Feeding systems (switching positioner, conveyor, etc.)

- Applications on a variety of material types:

Metal

Wood

Solid Surface

Composite

Plastic

Applications

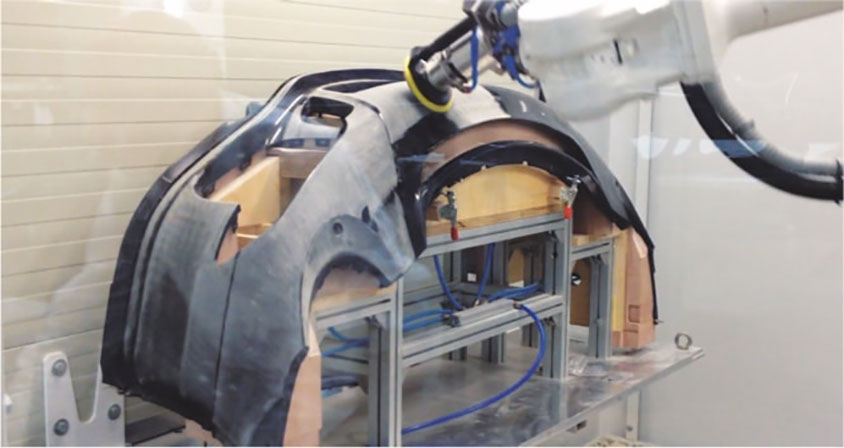

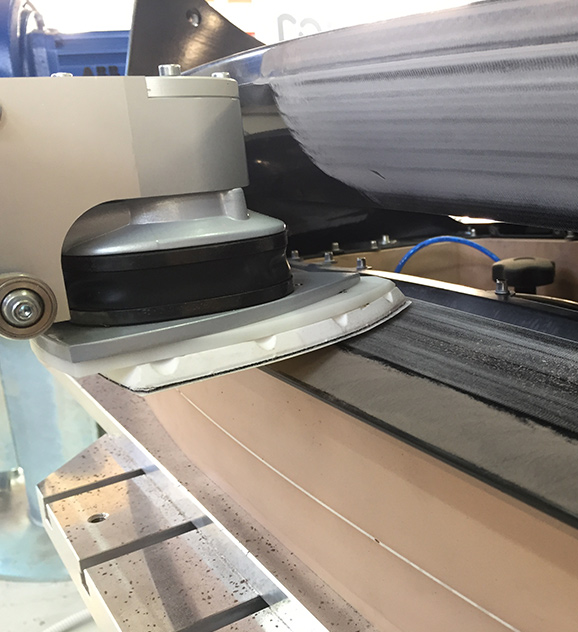

Robotic Sanding

Robotic sanding of the complex shapes and different material to achieve constant and high quality results with safer and cleaner work enviroment.

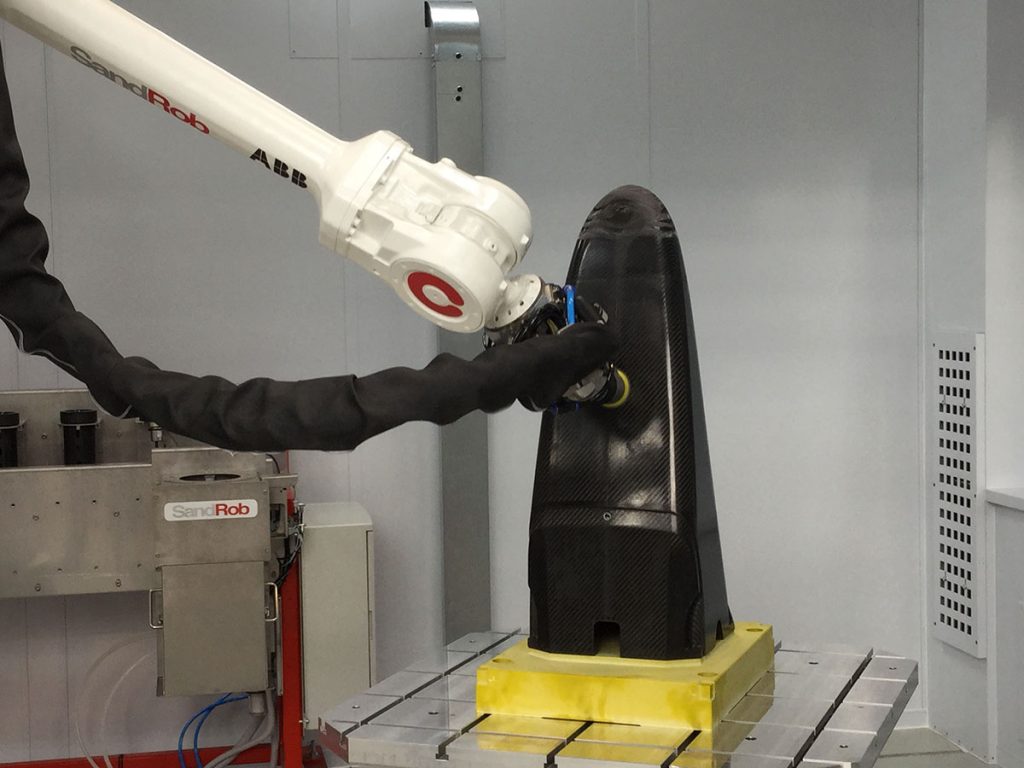

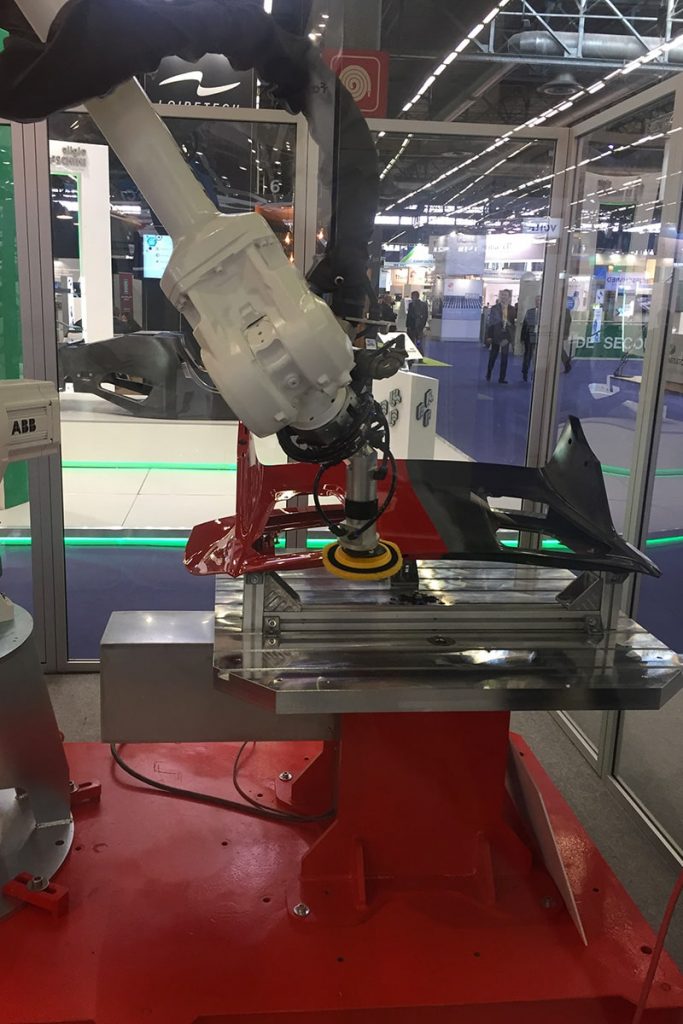

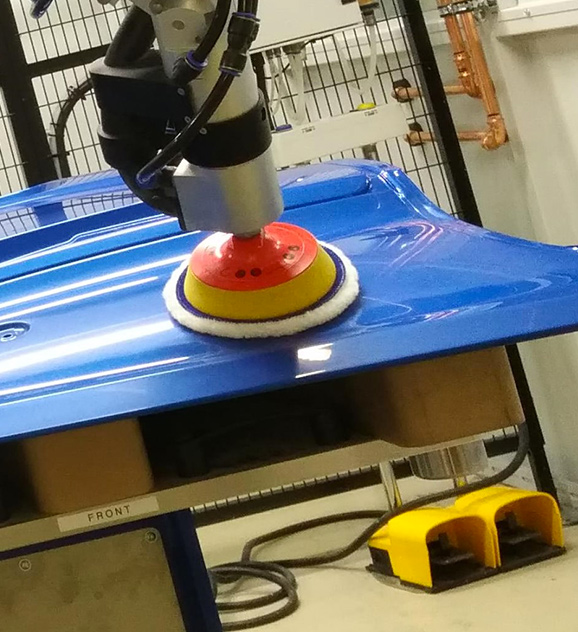

Robotic Polishing

SandRob allows you to quickly obtain regular polishing results, meeting functional needs, combining the use of different grit sandpapers and a polishing paste

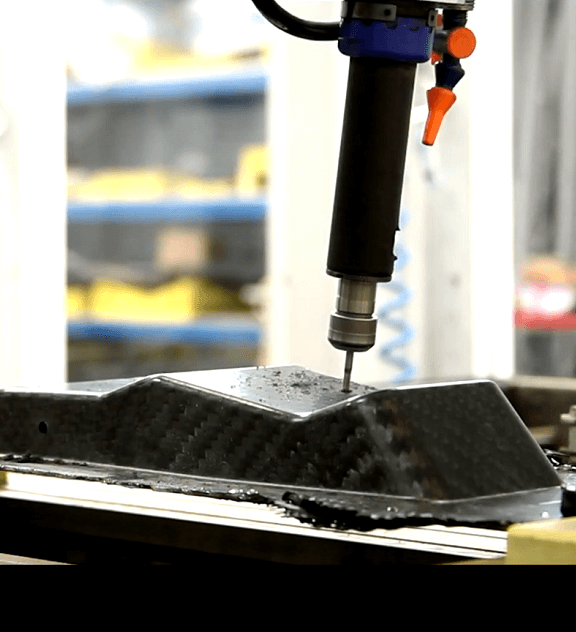

Robotic Drilling

SandRob performs the operations of drilling and cutting on complex shapes to manage the critical stages of contour cutting, drilling holes, opening slots, reaming and cutting panels.

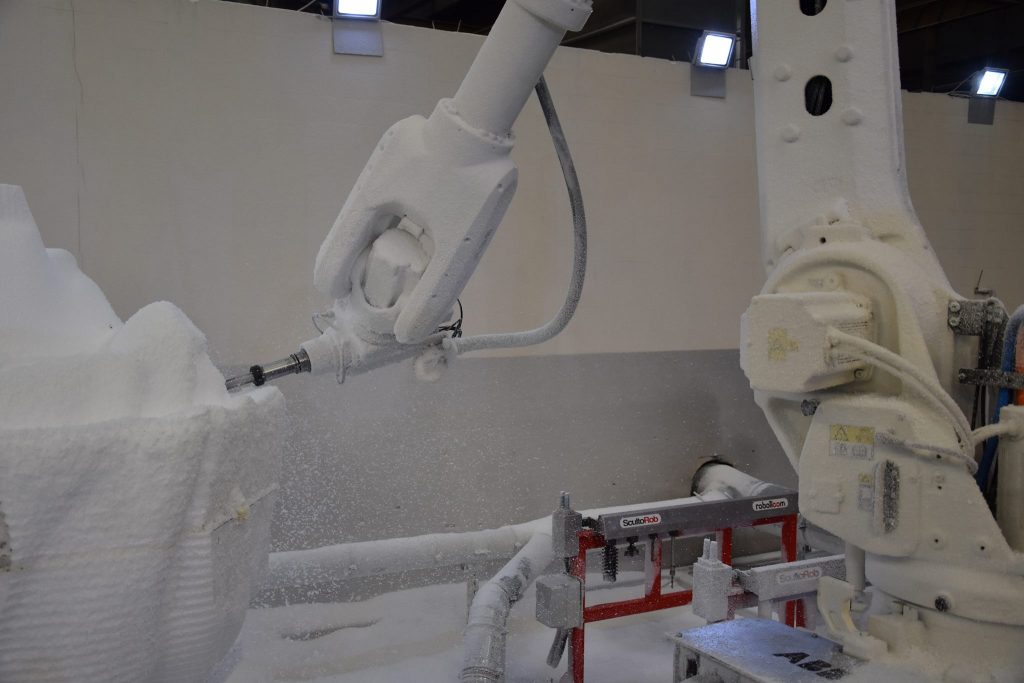

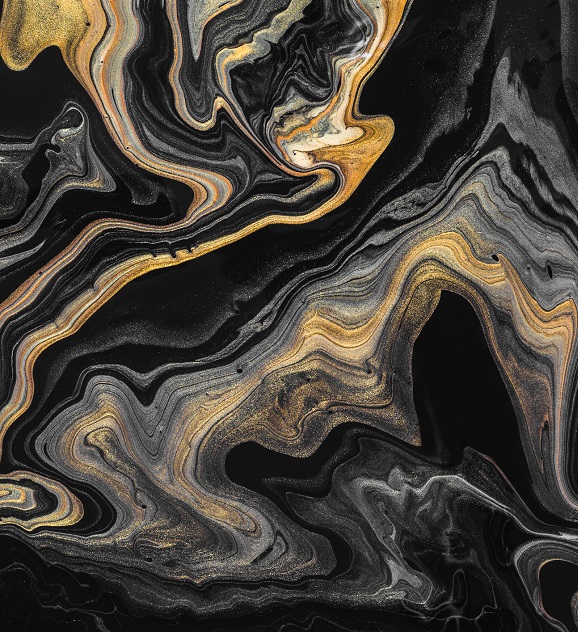

Machining and Carving

Machine and Carve 3D elements in a wide range of materials from natural stone to polystyrene.

Cutting and Trimming

Performs cutting, trimming and drilling to manage the critical stages of contour cutting.

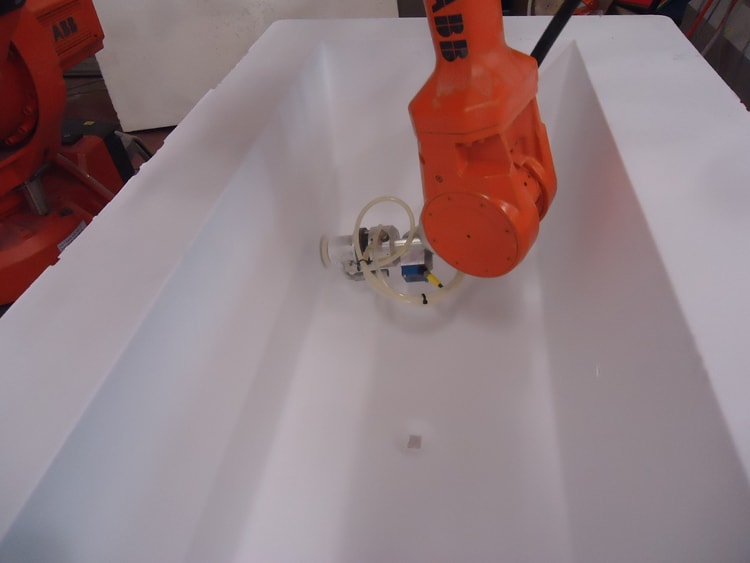

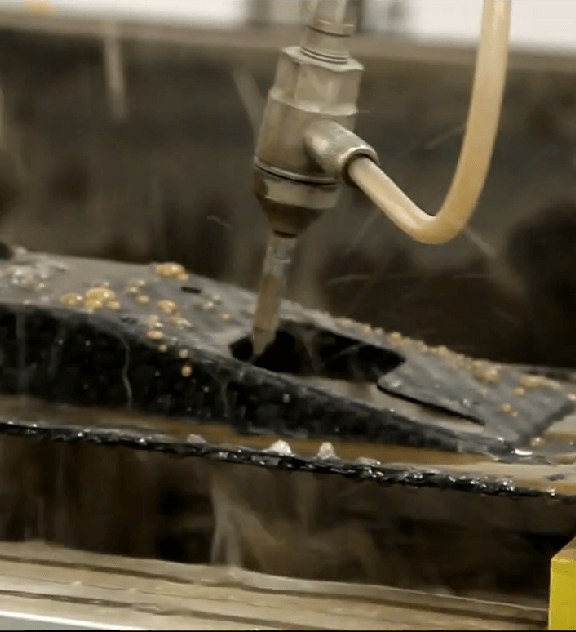

Water Jet

Perform the exact and precise control needed to produce the highest quality cuts on complex surfaces.

Industries

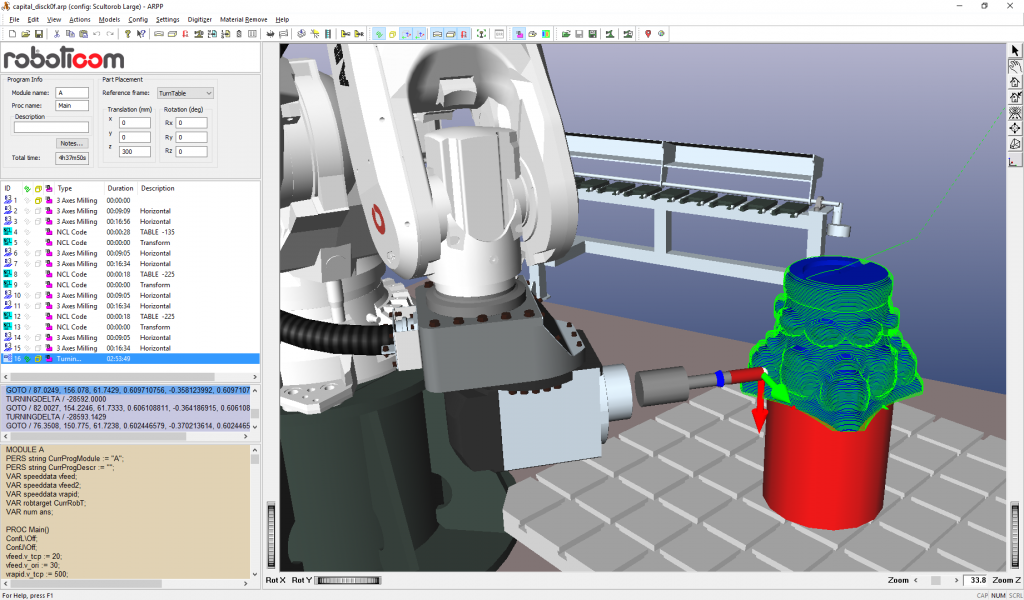

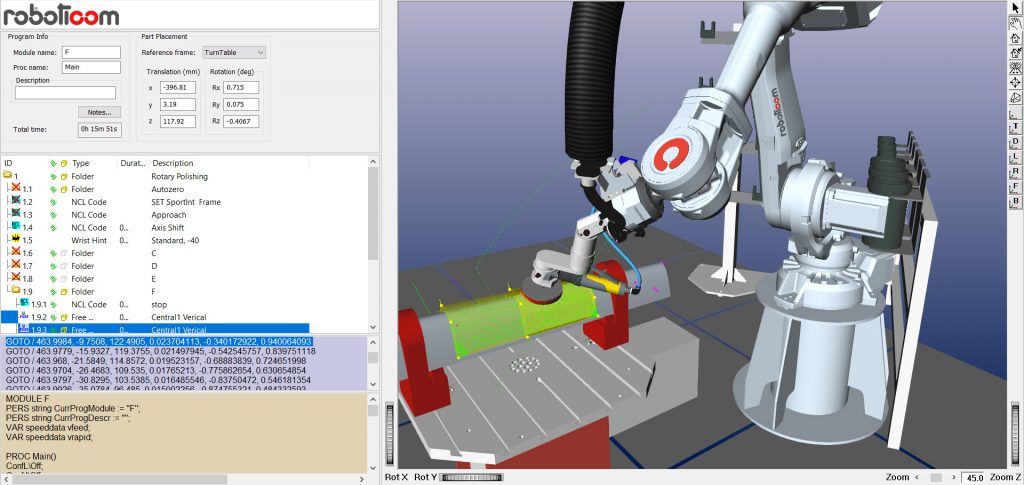

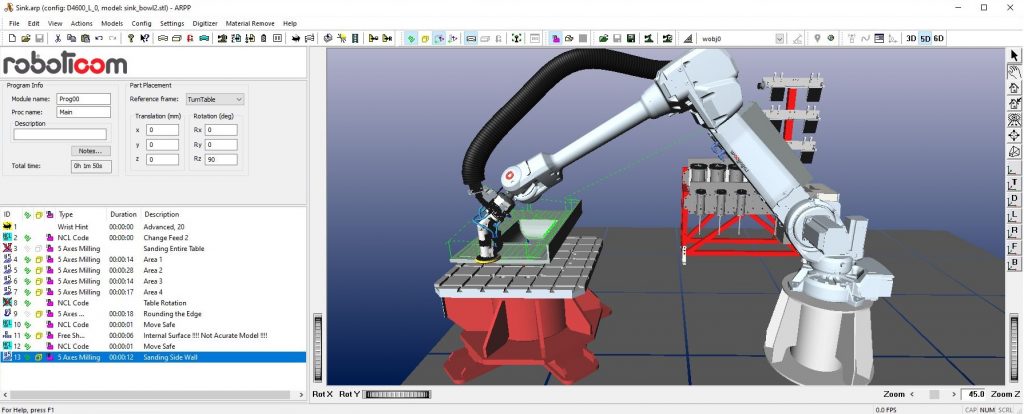

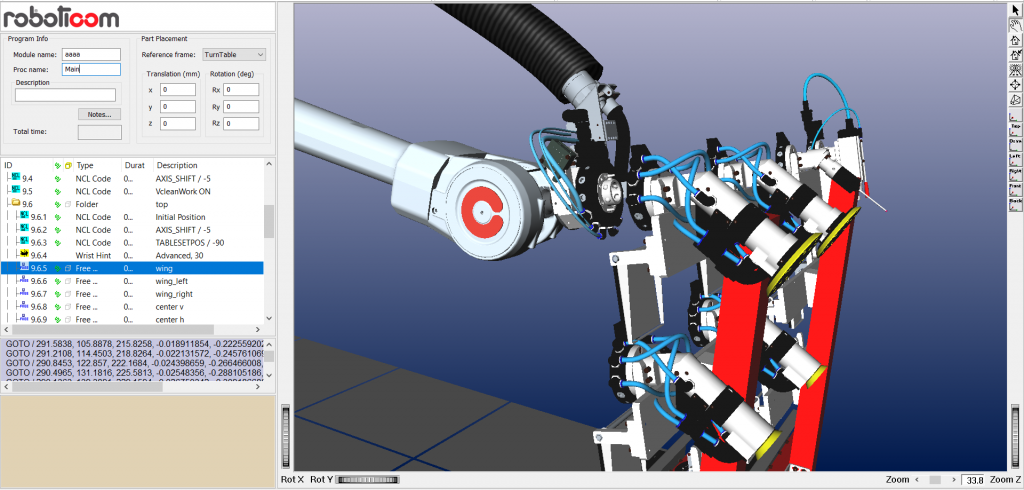

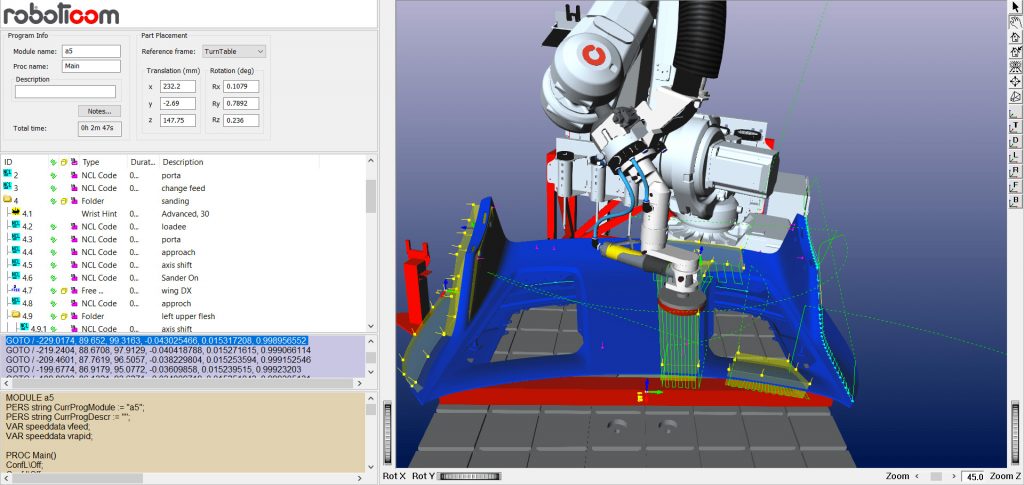

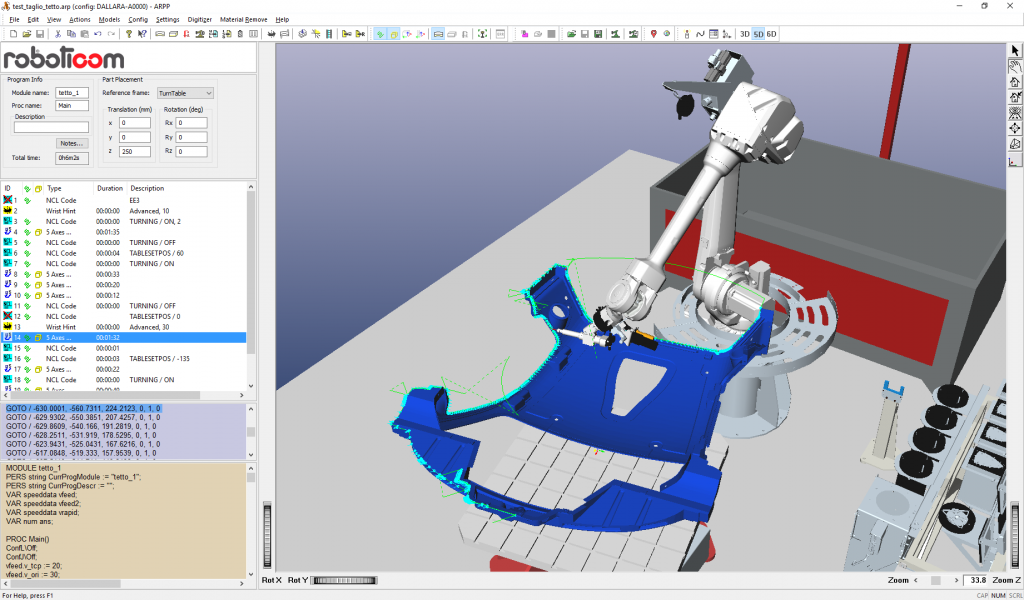

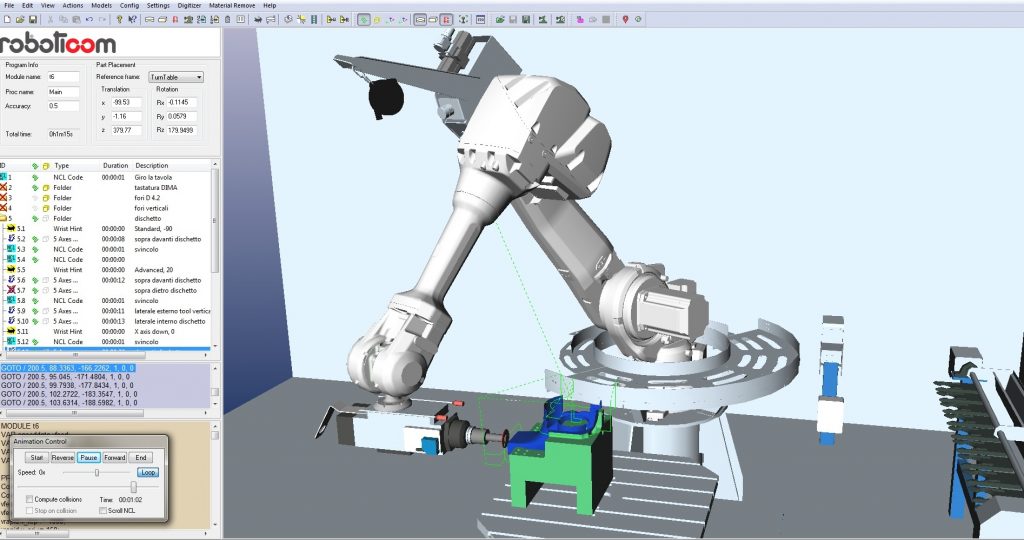

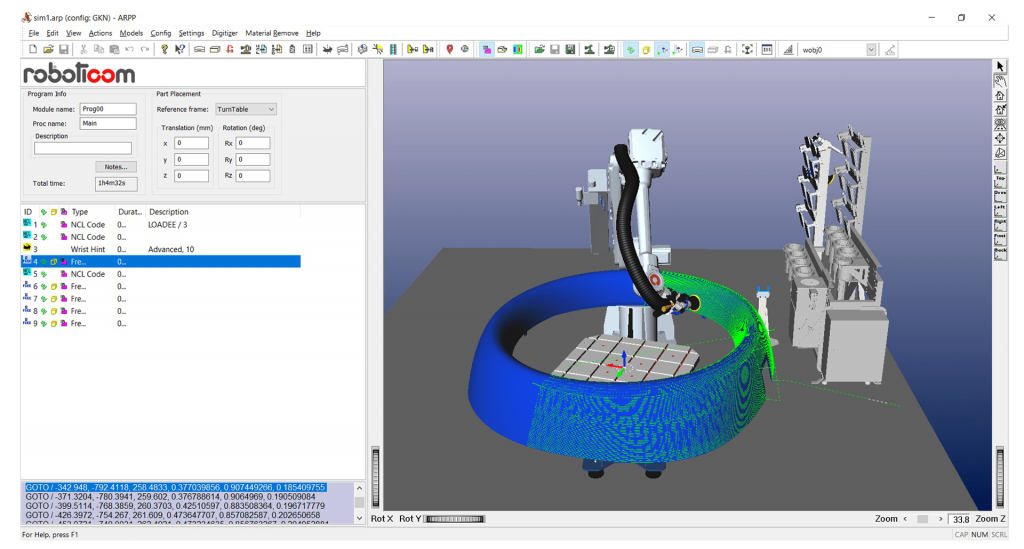

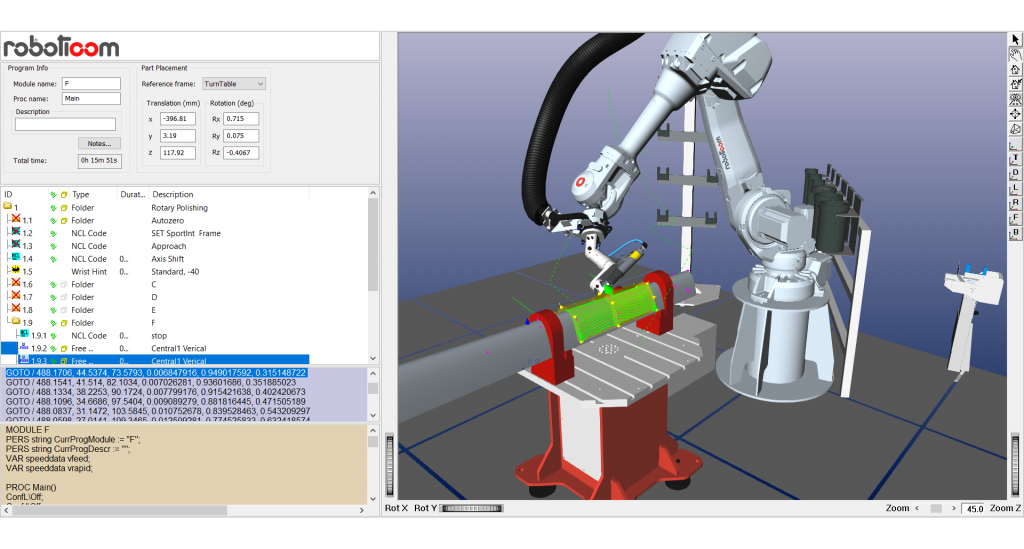

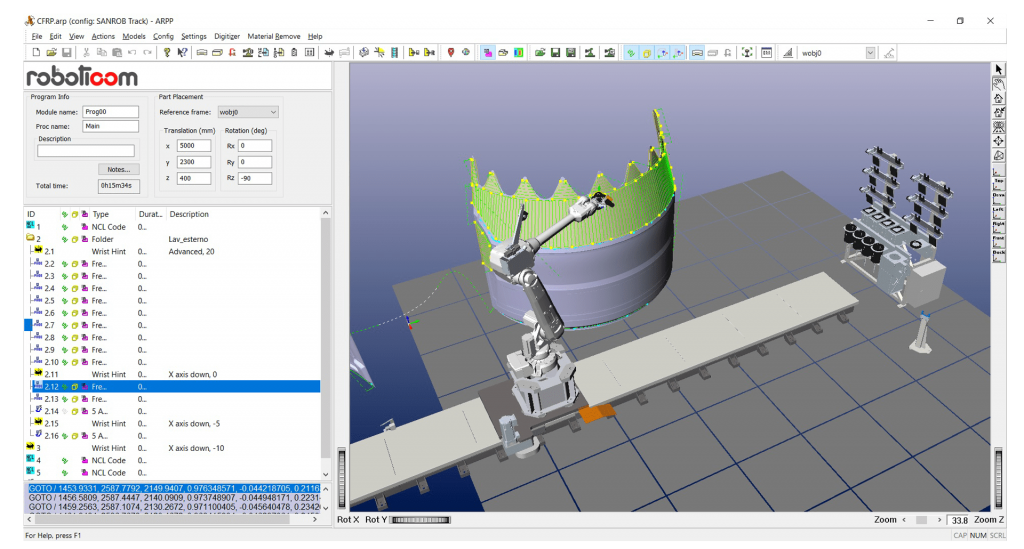

ARPP® Software

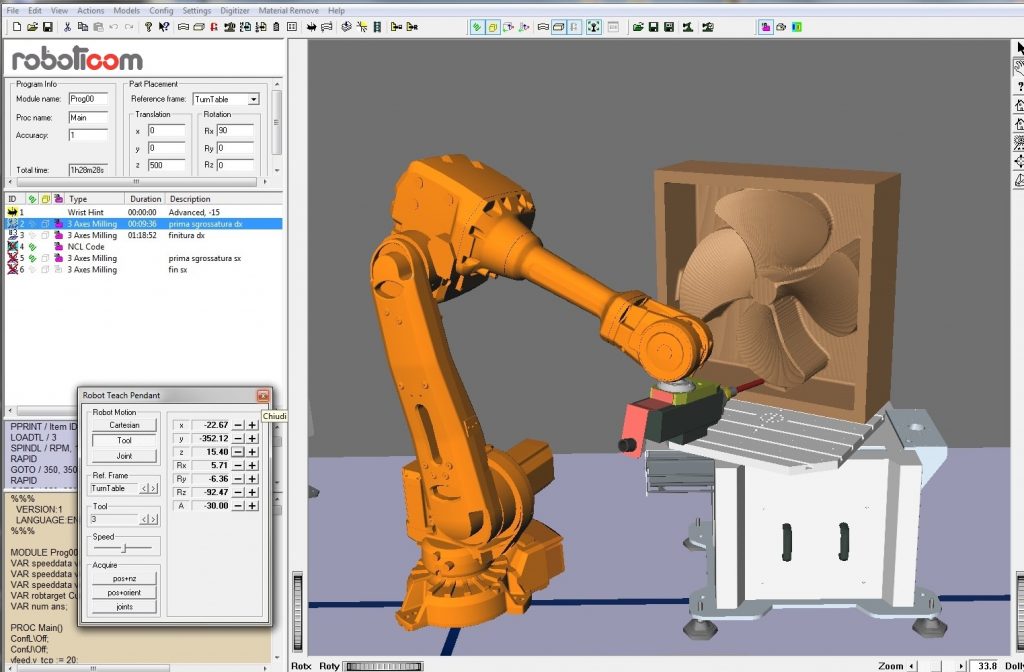

ARPP® is the in-house robot simulator. It is the easiest and most powerful software on the market that allows you to completely manage the robot without the use of any other additional software.

ARPP® owns CAM functionalities that generate optimized tool paths for artistic works. This unique solution ensures a quick learning time and provides simple procedures for the technicians.

Gallery

- All

- Sanding

- Polishing

- Cutting

- Carving

- Drilling

- Trimming

- Sculpting

Contact Us

19810 Asheville Highway Suite 101, Landrum, South Carolina 29356

hello@roboticom.us

(949) 238.6323

Upcoming Events

Industry News

Roboticom Blog