ORTIS ENTERPRISE

ORTIS is a robotic milling system able to produce any type of model necessary to create custom orthoses and prosthesis, leg-foot braces, scoliosis treatment corsets, foam aesthetic covers, orthopedic seats, prosthesis sockets, cranial correction helmets.

About ORTIS™ Enterprise

ORTIS™ Enterprise is the configuration that allows to reach the maximum productivity (average daily production of 20 models and more) without limitations or compromises on the working area (1200x1200x1800 mm).

ORTIS™ Enterprise is installed on an industrial floor with walls and partitions that delimit its access area; the features of this configuration will allow you to work in the most automated and efficient way.

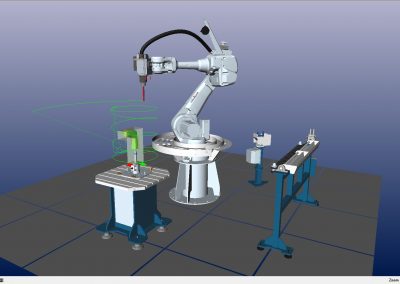

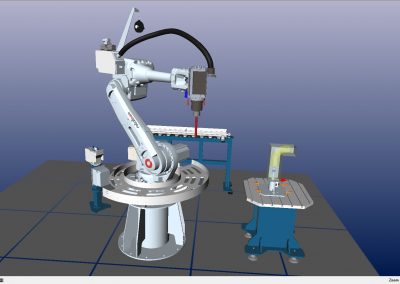

The installation includes the robot (maximum reach over 2 meters), the turntable, the toolbox (up to 10 tool positions) and the presetting laser; the distinctive feature of this system is a powerfull electro spindle with the automatic tool change.

System Programming

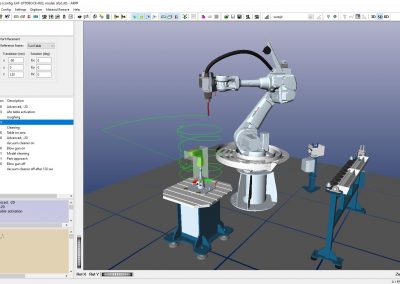

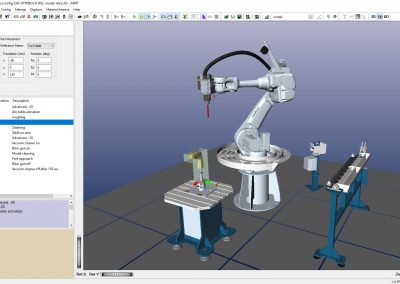

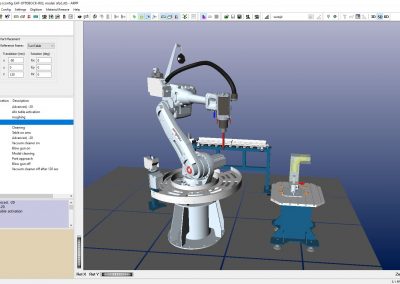

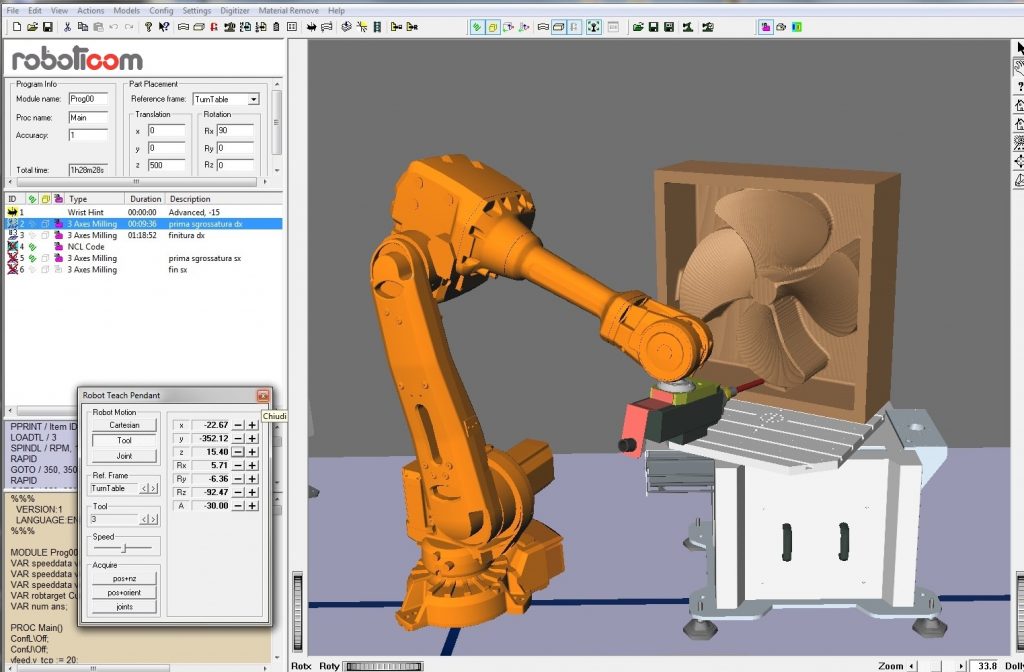

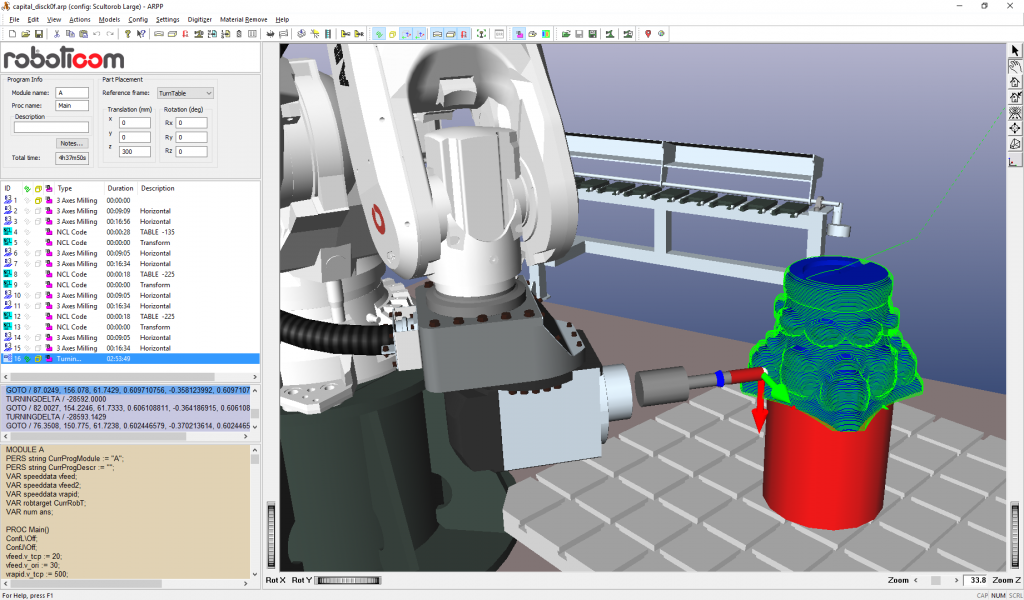

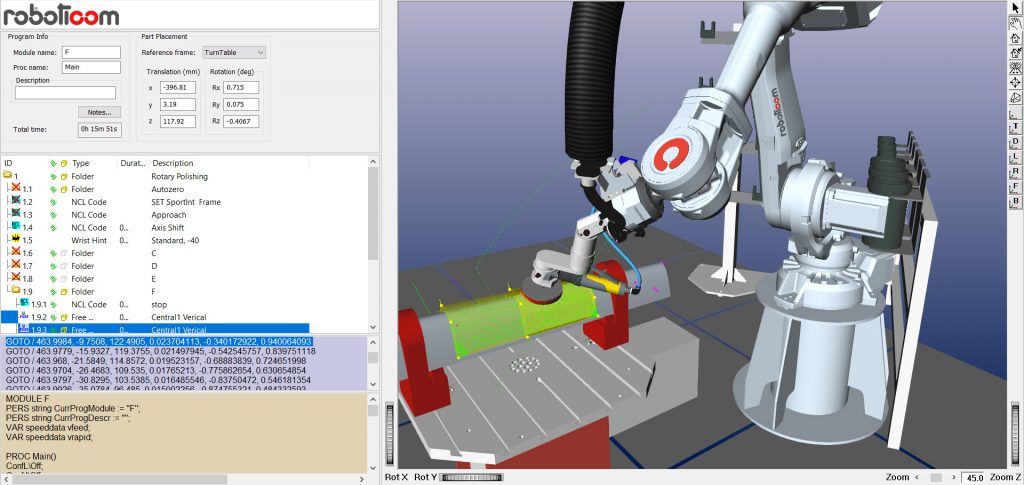

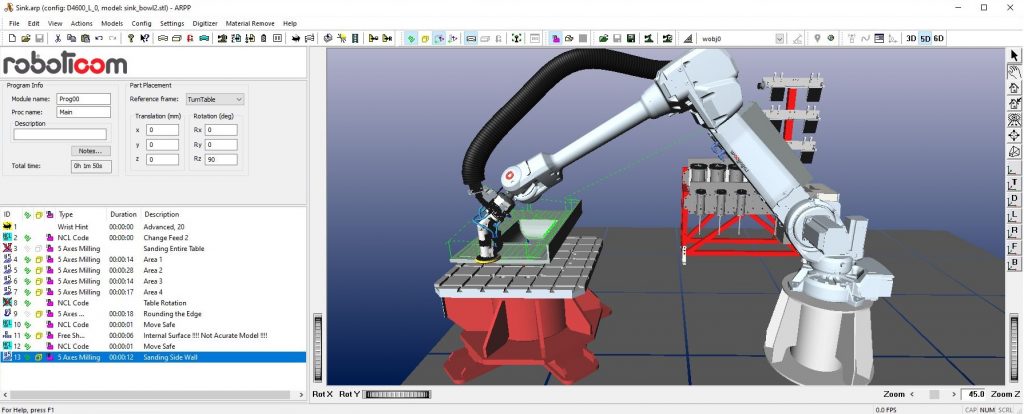

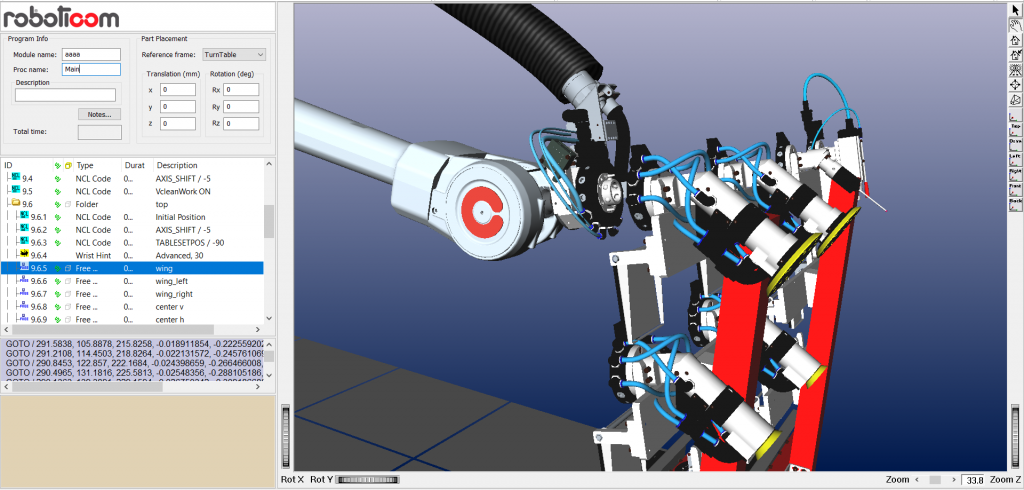

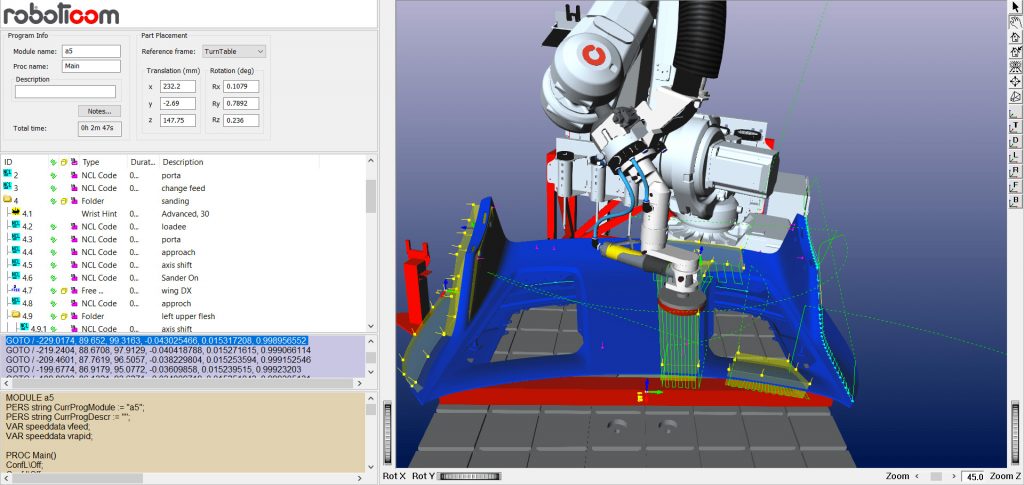

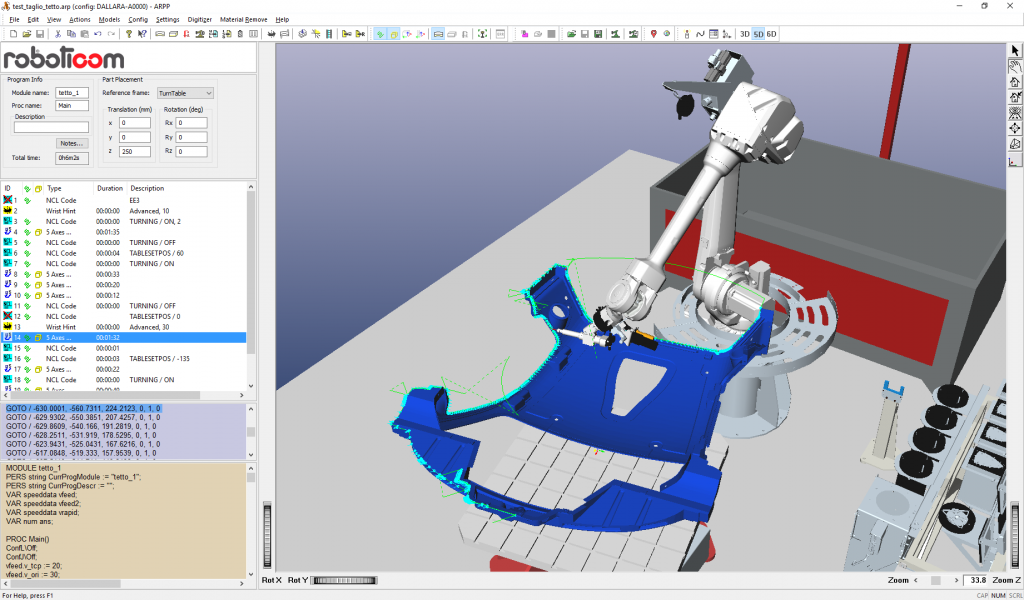

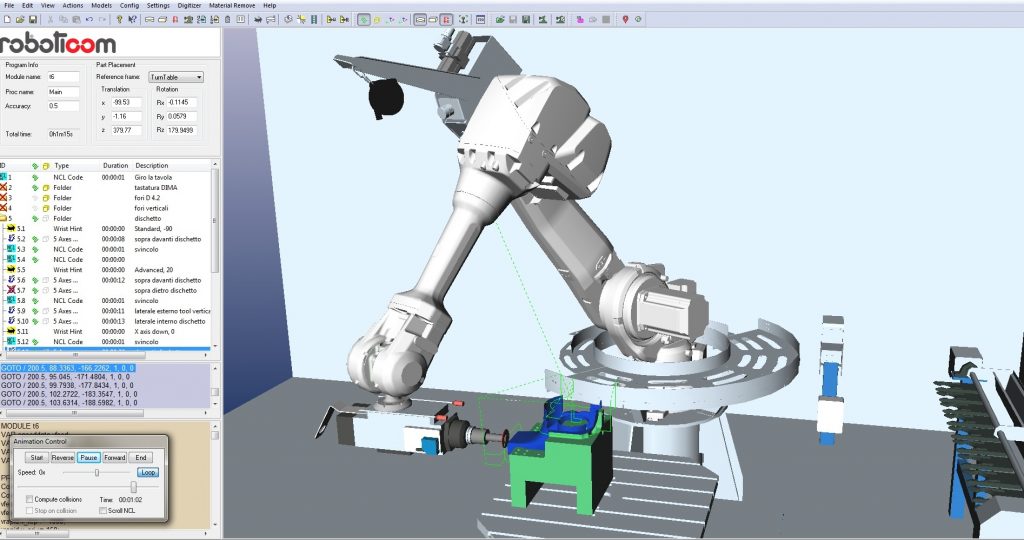

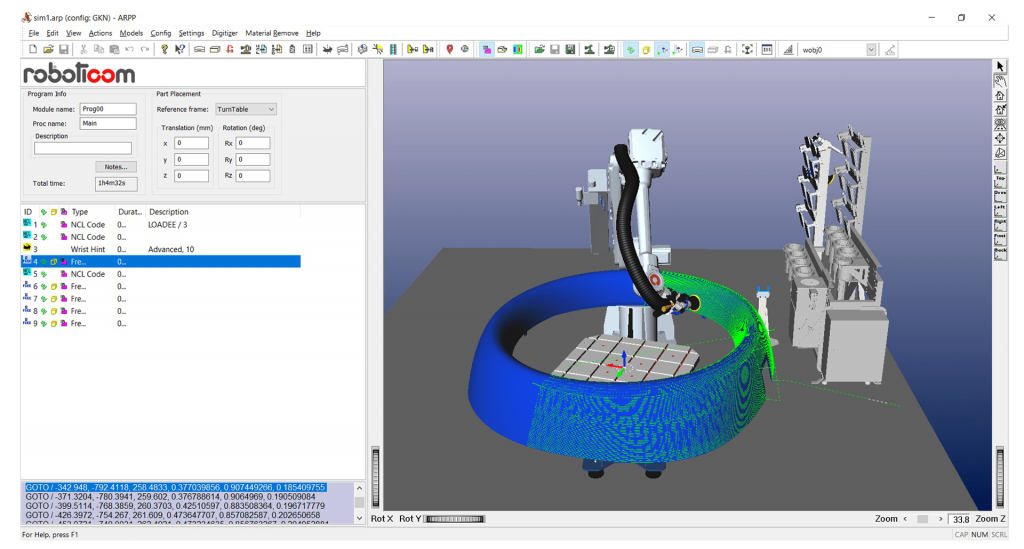

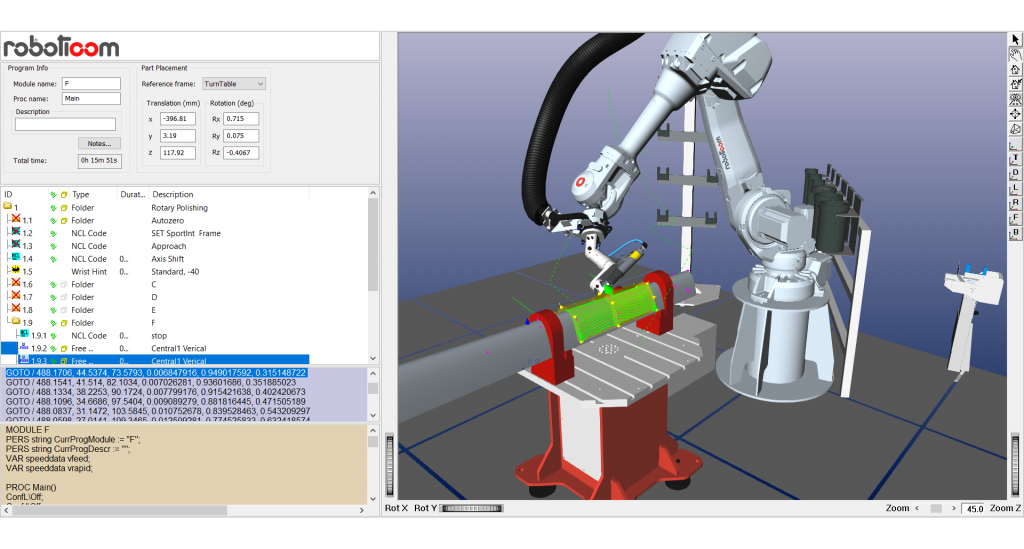

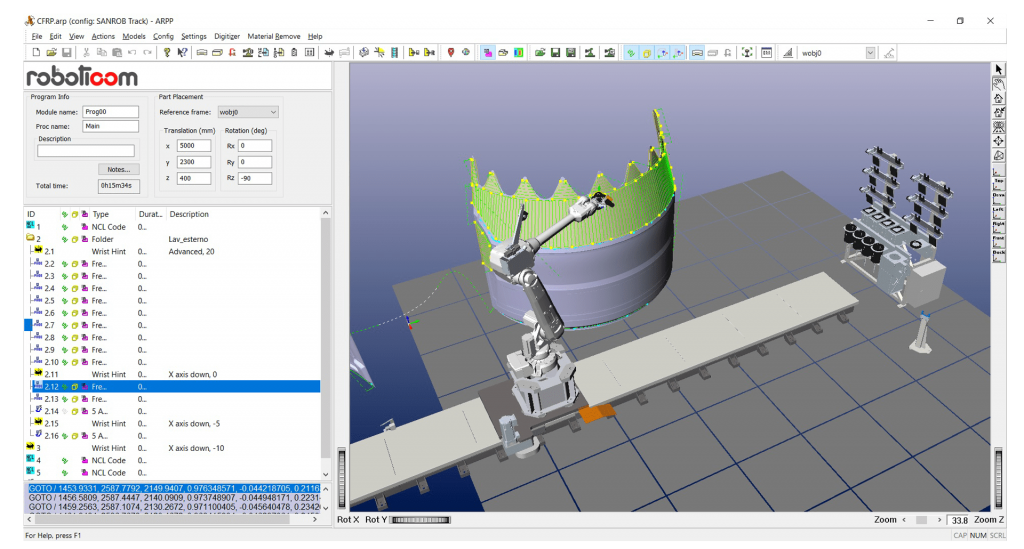

A license of our ARPP® software ships with the system. ARPP® is powered by 5-axis a tool path generator (ARPPCAM), and allows for a precise ahead-of-time 3D simulation of the milling and material removal process.

Open System

ORTIS can be used with any 3D scanner or software that makes use of industry-standard formats (STL, AOP, VRML, …).

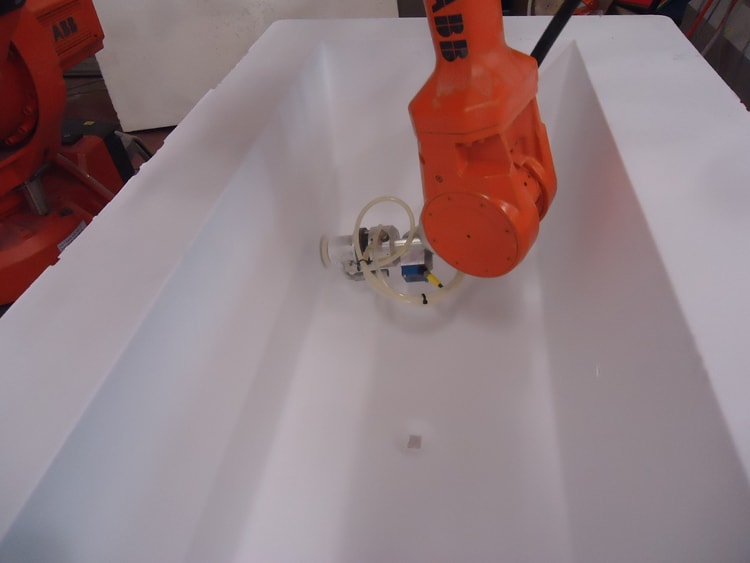

Robot type: ABB, 6 axes, 40-60 kg payload on the wrist, working area from 2000 to 2500 mm

Turntable: In-house designed, it is the 7th interpolated axis. 700×700 mm aluminum working plate, 60 rpm (Possibility to have an additional turntable or fixed table to increase productivity).

Laser calibration: The standard setup includes a laser guide to perform automatic tool length calibration.

Working volume: Blocks up to 1200x1200x1800 mm. Possibility to expand the the supporting plate for bigger blocks.

Compressed air

Minimum 6 bar

System minimum area: 4000x4000x3000 mm

Contol unit area: 1000x1000x2000 mm.

Weight: Robot + base : 650 kg, Turntable: 270 kg

Control unit: 250 kg, Toolbox: 280 kg

Power supply: 380VAC three phase, 50-60Hz, 15 KVA

(5,5 kw kw average consumption)

Other ORTIS™ Products

ORTIS™ Essential

Essential need of any small to medium size fabrication shop.Working area of 24x24x40 in. Enclosed system to control dust and noise, Small footprint.

ORTIS™ Professional

Intermediate configuration for an average production of 10-15 models per day. Working area of 48x48x71in. Standard as well as customized configurations available.

Compare ORTIS™ Models

|  |  | |

|---|---|---|---|

| Features | ORTIS Essential | ORTIS Professional | ORTIS Enterprise |

| Robot Type | ABB 6-Axes 6 kg (13 lbs) Payload on the Wrist Working Area Approximately 1000 mm (3 feet) | ABB 6-Axes or KUKA 6-Axes 20 kg (44 lbs) Payload on the Wrist Working Area Approximately 1600 mm (5 feet) | ABB 6-Axes or KUKA 6-Axes 40-60 kg (88-132 Ibs) Payload on the Wrist Working Area from 2.000 to 2.500 mm (6 feet to 8 feet) |

| Seventh Interpolated Axis Aluminum Turntable | 450 x 450 mm (18”x18”) Working Plate, 60 rpm System Integrated in Containment Box | 700 x 700 mm (28”x 28”) Working Plate, 60 rpm | 700 x 700 mm (28”x 28”) Working Plate, 60 rpm |

| 380V Three-phase Electro Spindle | 1.0 KW 24.000 rpm Auto Cooling System Up to ER20 Collect (Tool Shank Diameters from 2 to 12 mm) Manual Tool Change | 3.6 KW 24.000 rpm Fan-Cooling Up to ER30 Collect (Tool Shank Diameters from 3 to 20 mm) Manual Tool Change | 4.0 KW 24.000 rpm Fan-Cooling ISO30 Tool Holders (Tool Shank Diameters from 2 to 20 mm) Automatic Tool Change |

| Presenting Laser | Laser Device Automatically Measures the Tool Length | Laser Device Automatically Measures the Tool Length | Laser Device Automatically Measures the Tool Length |

| Tool Box | 10-position toolbox for ISO30 Tool Holders The robot deposits the holder with the actual tool in the box and automatically takes the new required tool. | ||

| Work Area | Processes blocks up to 600 x 600 x 1000 mm (2 feet x 2 feet x 3 feet) | Processes blocks up to 700 x 700 x 1200 mm (3 feet x 3 feet x 5 feet) or more, with the adequate extensions for the supporting plate | Processes blocks up to 1200 x 1200 x 1800 mm (4 feet x 4 feet x 6 feet ) or more, with the adequate extensions for the supporting plate |

| Dimensions | The Complete System: The Robot Controller is housed in an aluminum box, prearranged for chip suction. The dimensions are: 1700 length x 1250 width x 2450 height mm (6 feet length x 4 feet width x 8 feet height) | Installation on Industrial Floor Minimum Area: 3000 x 3000 x 2700 mm (10 feet x 10 feet x 9 feet) Additional Area for Robot Control Unit: 1000 x 1000 x 2000 mm (3 feet x 3 feet x 7 feet) To increase the productivity, you can install more than one turntable/ xed table around the robot | Installation on Industrial Floor Minimum Area: 4000 x 4000 x 3000 mm (13 feet x13 feet x 10 feet) Additional Area for Robot Control Unit: 1000 x 1000 x 2000 mm (3 feet x 3 feet x 7 feet) To increase the productivity, you can install more than one turntable/ xed table around the robot |

| Weight | A total of about 600 kg (1300 Ibs) | Robot with its own base: 550 kg (1200 lbs) Turntable: 270 kg (600 lbs) Control unit: 250 kg (550 lbs) | Robot with its own base: 650 kg (1500 lbs) * Turntable: 270 kg (600 lbs) Control Unit: 250 kg (550 lbs) Tool Box: 280 kg (625 lbs) |

| Noise Level | <75 dB | <75 dB on a typical installation | <75 dB on a typical installation |

| Compressed Air | Optional, at least 3 bar | Minimum 6 bar | Minimum 6 bar |

ARPP® Software

ARPP® is the in-house robot simulator. It is the easiest and most powerful software on the market that allows you to completely manage the robot without the use of any other additional software.

ARPP® owns CAM functionalities that generate optimized tool paths for artistic works. This unique solution ensures a quick learning time and provides simple procedures for the technicians.

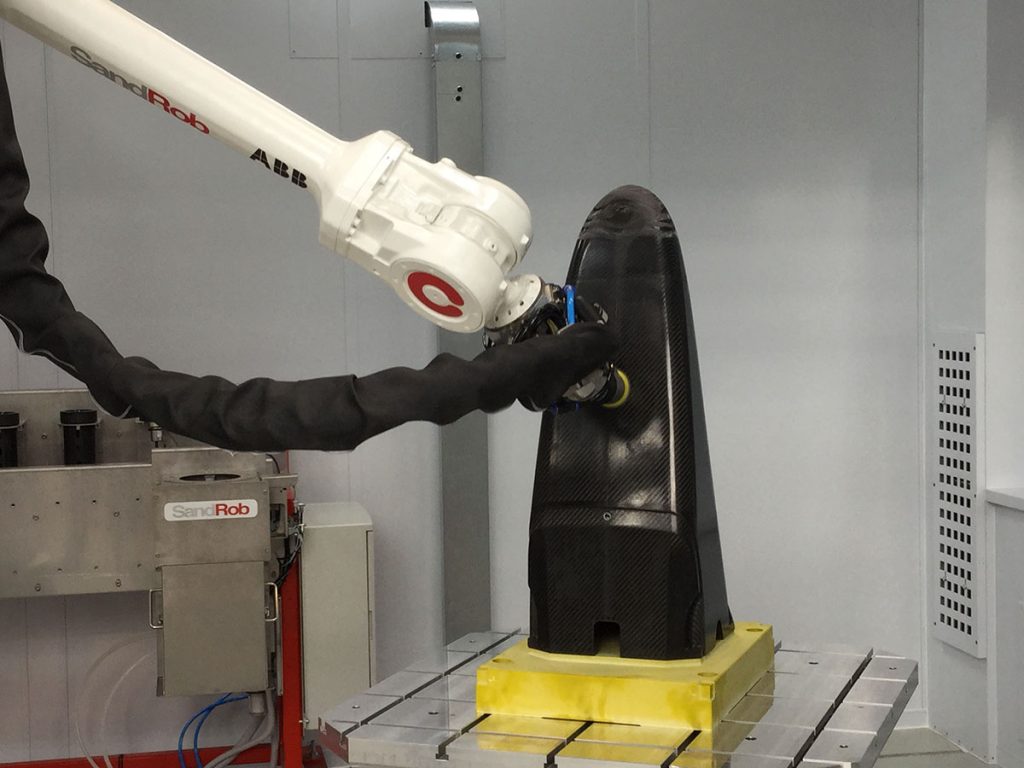

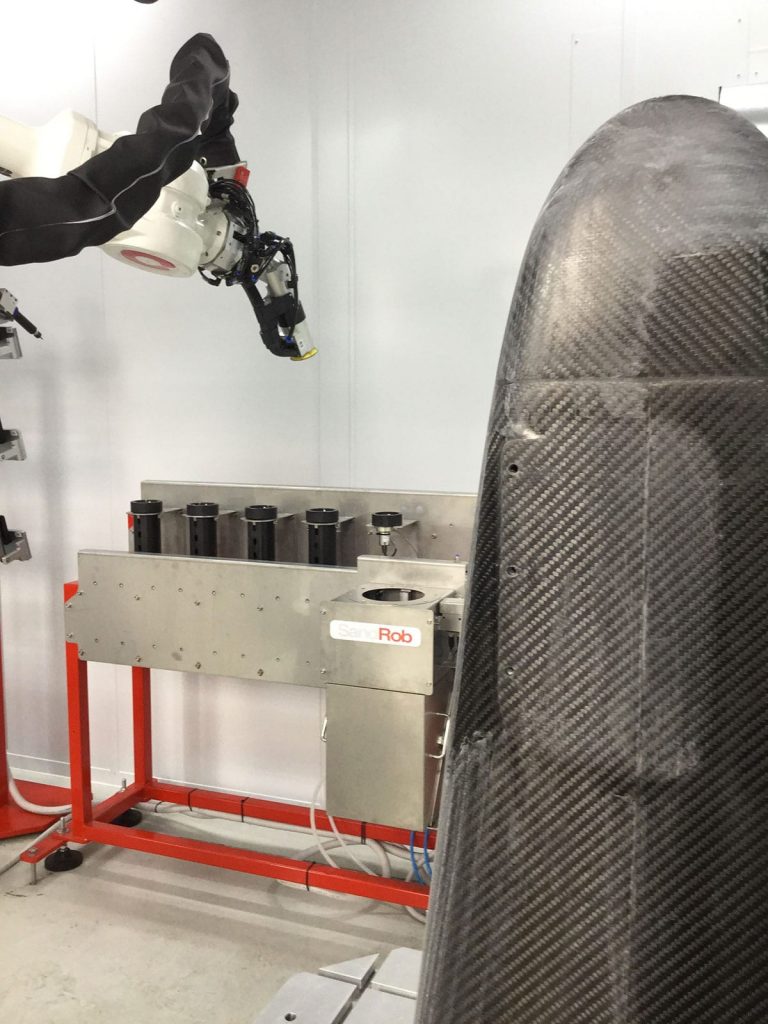

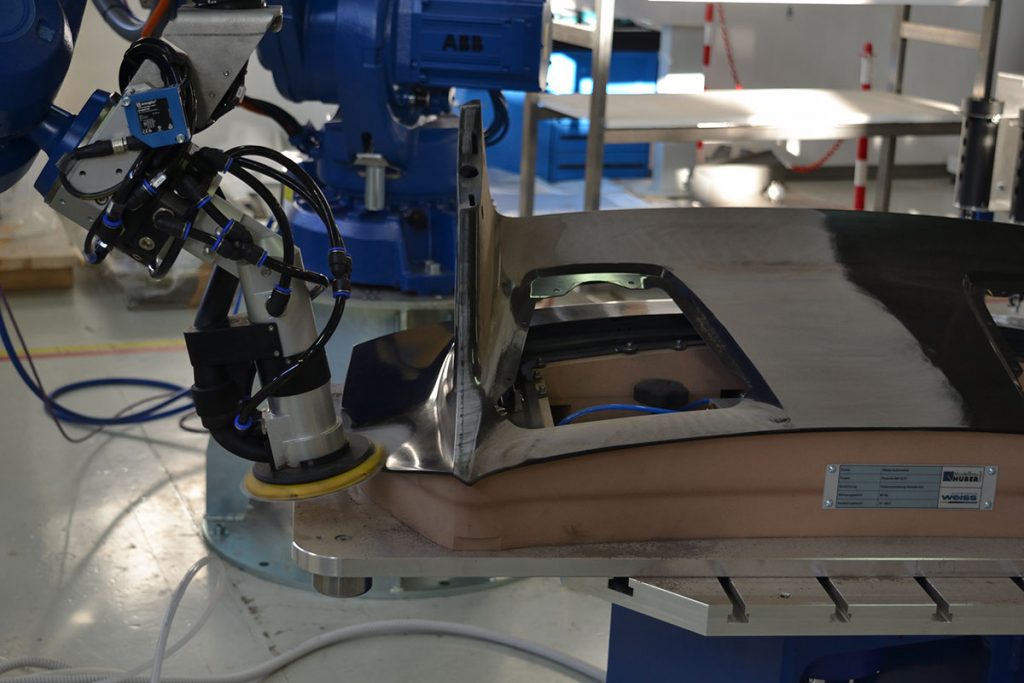

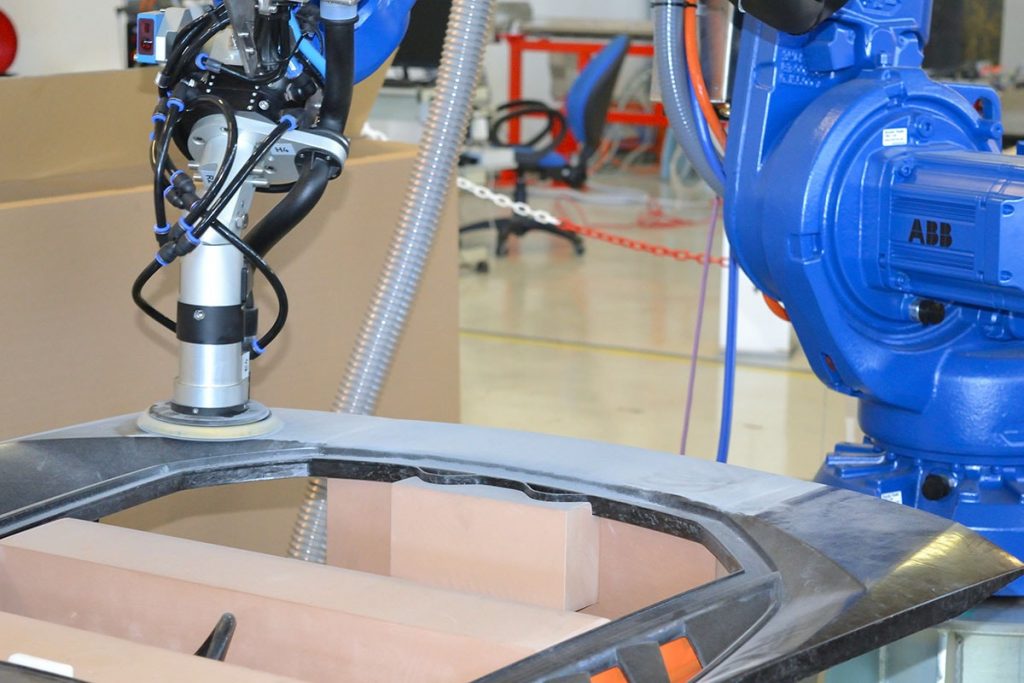

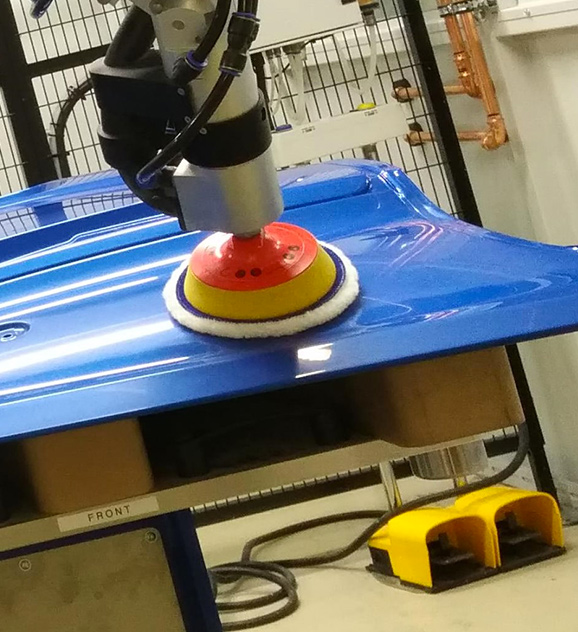

Gallery

- All

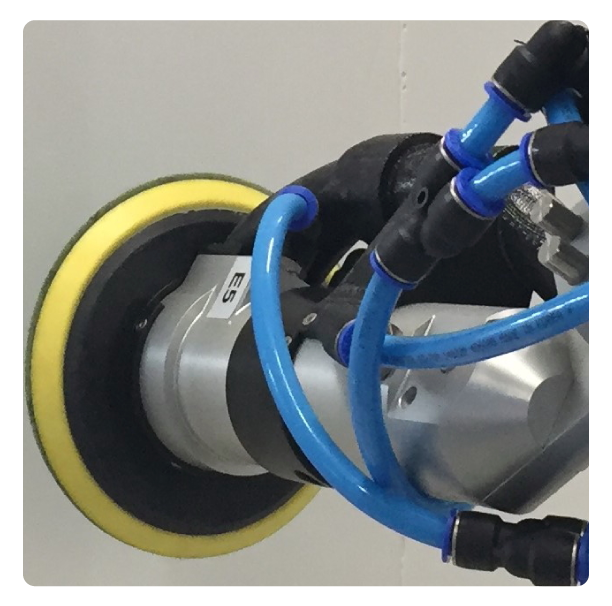

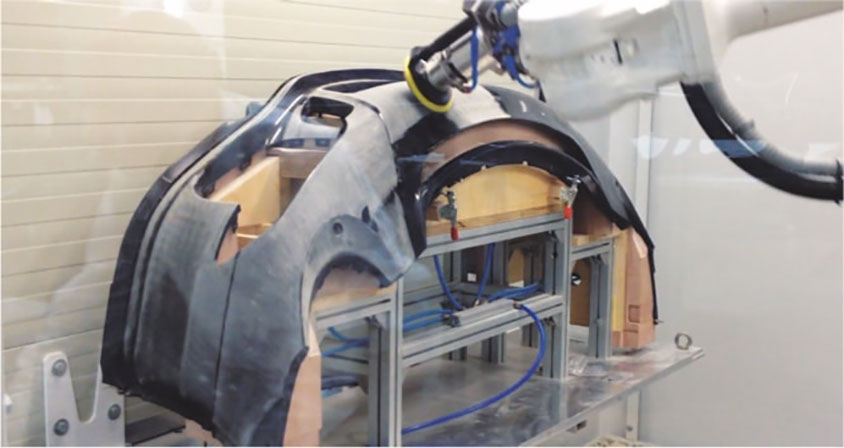

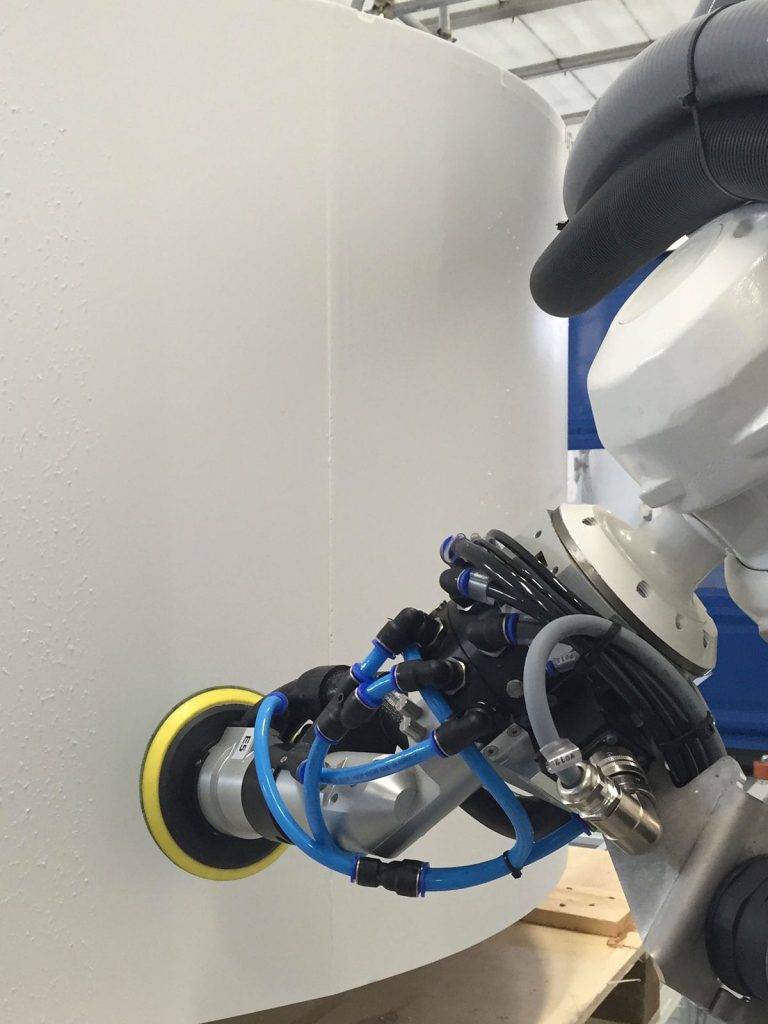

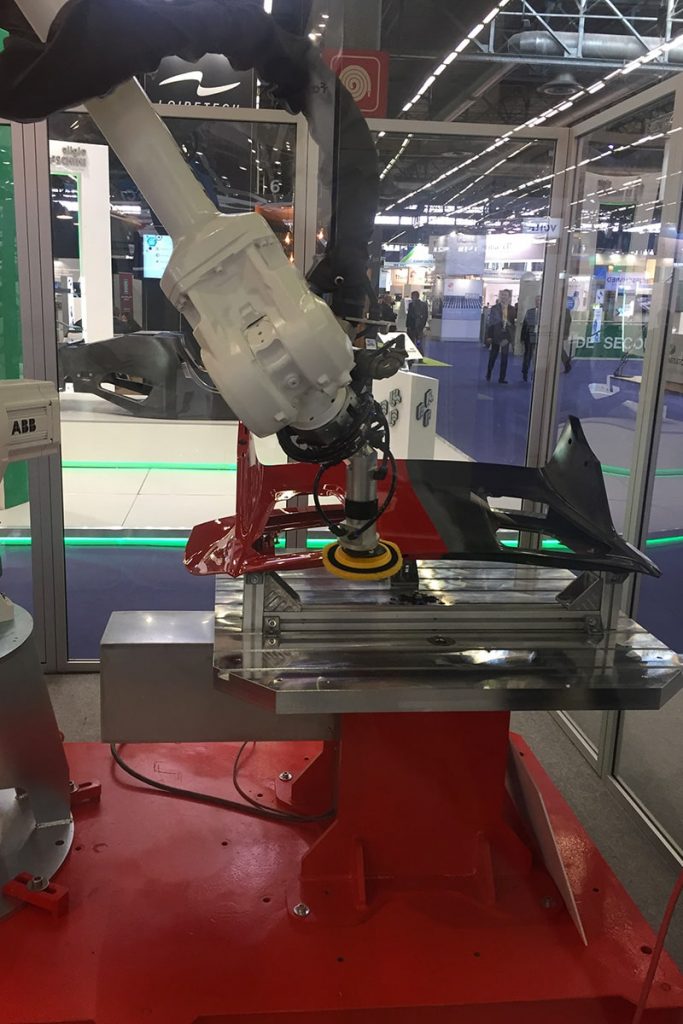

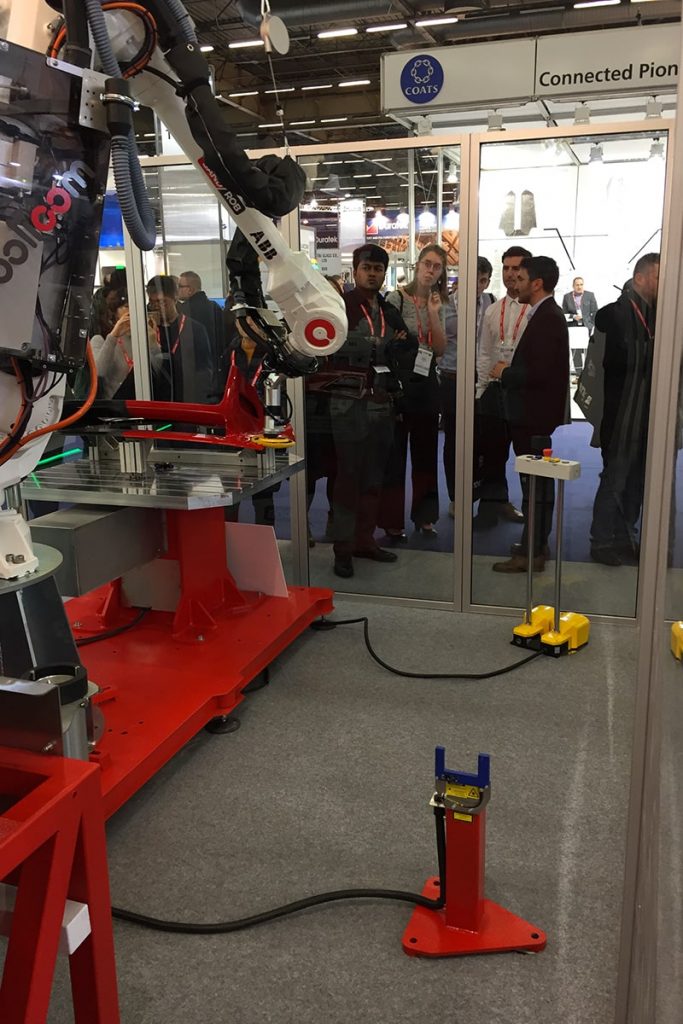

- Sanding

- Polishing

- Cutting

- Carving

- Drilling

- Trimming

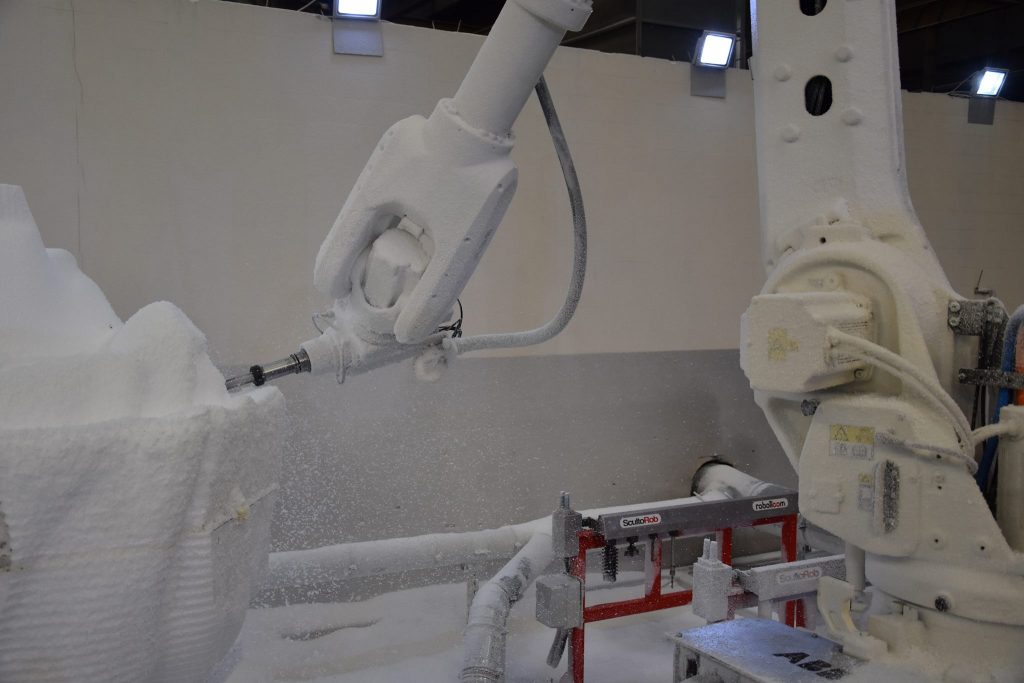

- Sculpting

Contact Us

19810 Asheville Highway Suite 101, Landrum, South Carolina 29356

hello@roboticom.us

(949) 238.6323

Upcoming Events

Industry News

Roboticom Blog